Tesla buys manufacturing automation company (TSLA)

BI Intelligence

This story was delivered to BI Intelligence IoT Briefing subscribers. To learn more and subscribe, please click here.

Tesla has acquired Perbix, an automotive supplier that specializes in automated manufacturing machines, for an undisclosed sum, reports Bloomberg.

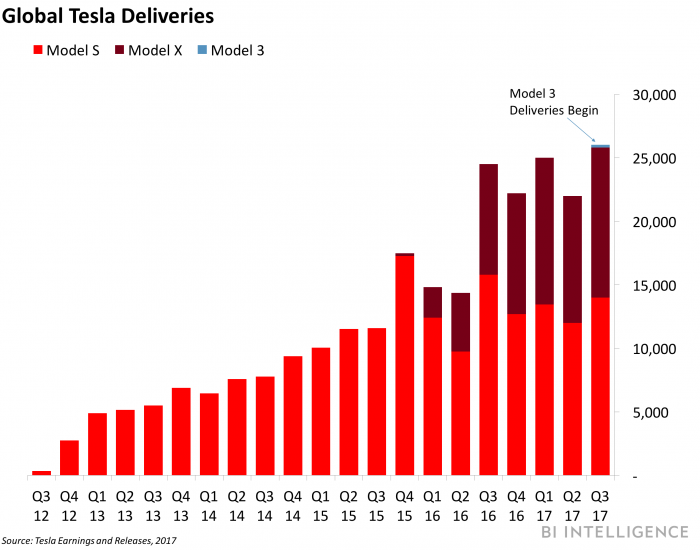

The automaker began production of its new, more affordable Model 3 sedan over the summer, but it has failed to meet production estimates and has delivered far fewer cars than anticipated due to manufacturing issues, which the company discussed last week on its quarterly earnings call. Acquiring Perbix, which is already a Tesla supplier, could be a step toward rectifying these problems.

Manufacturing issues have prevented Tesla from reaching its production goals, with the company producing just 266 vehicles last quarter, far below its target of 1,600.CEO Elon Musk discussed a number of bottlenecks that were holding back production on the earnings call, focusing primarily on issues with the company’s battery-production facilities, which manufacture the highly specific batteries that Tesla’s vehicles need.

But another, more worrisome issue was the company’s need to move parts of production away from the automated machine line intended to complete vehicles, and to make some parts by hand. Production of the company’s older vehicles had been less reliant on automation, which meant shifts in procedures and labor allocation allowed it to hit production goals despite manufacturing hiccups. To make the Model 3 more affordable, though, it’s highly reliant on automated manufacturing, so problems that were minor with prior vehicles are magnified now.

Acquiring Perbix could help alleviate these issues. Perbix’s automated machines are used in manufacturing facilities on production lines, allowing the machinery in a factory to operate on its own. This lets companies keep their facilities running longer without overly taxing employees, and allows repeated procedures that are more reliable than manual manufacturing.

Bringing Perbix, an existing supplier, in-house will allow Tesla to put the company’s engineers to work refining the machinery on the Tesla’s production lines and letting it rely more heavily on automated manufacturing rather than needing to resort to manual fabrication. Improving its manufacturing capabilities is the only way that Tesla will be able to reach its lofty production goal of 5,000 Model 3s per week by March 2018.

To receive stories like this one directly to your inbox every morning, sign up for the Internet of Things Briefing newsletter. Click here to learn more about how you can gain risk-free access today.

See Also:

Yahoo News

Yahoo News